Asoe Hose Manufacturing Inc. develops different types of trenchless pipe rehabilitation solutions to pressure pipes. Pipe-in Liner is the easiest to install.

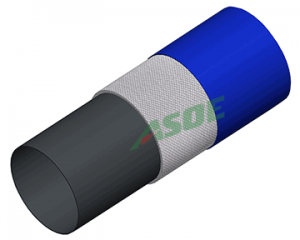

Pipe-in Liner is a Fabric Reinforced Flexible Plastic Hose (FRFPH). The basic installation procedure is as follows:

1. Fold firstly Pipe-in Liner into U-shape

2. Pull the liner into the host pipes

3. Expand the liner in the host pipes

Then the Pipe-in liner will work as a leakage-free liner inside the host pipes.

Pipe-in Liners are classified into four different series: Pipe-in Liner W Series, Pipe-in Liner O Series, Pipe-in Liner G series, and Pipe-in Liner H series.

Pipe-in Liner W series are used to rehabilitate pressure pipelines, including water main pipes and force mains at normal temperature. Pipe-in Liner O series are used to rehabilitate oil pipes both onshore and offshore. Pipe-in Liner G series are used to rehabilitate gas pipes both onshore and offshore. Pipe-in liner H series are used to rehabilitate pipes in municipal heat system. Pipe-in liner H series can resist a temperature up to 95° C (203° F); furthermore, Asoe is the first company in the world to develop this type of solution to rehabilitate hot water pipes.

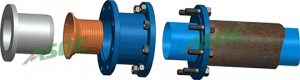

Besides liners, Asoe also supplies complete solutions and accessory equipment, including couplings to connect Pipe-in Liner with host pipes, equipment to install couplings, and technical consulting etc.

Pipe-in Liner solution is a semi-structurally independent rehabilitation technology. There is no connection between the host pipe and the liner; the liner works independently from the host pipe. The liner is rigid and maintains the round shape inside the host pipes when there is a vacuum inside the host pipe or when there is temporary external pressure on the host pipe.

ASTM installation guide and design guide are available upon request.

Connectors (PILC Couplings, Patent Protected)

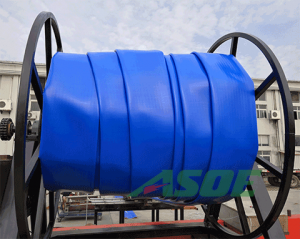

Installation

Specification

Sizes of host pipes can be rehabiliated: DN50-DN800 (2″-32″)

Reinforcement layer: Polyester or Kevlar

Length: 10m-6,000m (35ft-20,000ft)

CIPP solutions for gas pipes or water main pipes

SJ-HL liners, DJ-HL liners, SJL-HL liners are available for request.