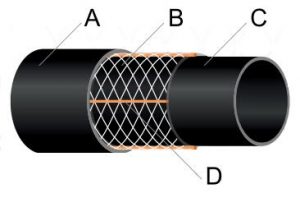

This hose is made from extruded thermoplastic polyether based polyurethane (TPU) with excellent wear & tear properties. The reinforcement is made from circular woven filament polyester yarn. The “extrusion through-the-weave” production method gives a very strong bonding between cover and lining as well as firmly encapsulating the woven polyester.

Incorporated copper wire is used to transfer static electricity.

Features & Benefits

- Lightweight and easy to handle

- High Pressure rating

- Good resistance to fuel and chemicals

- Easy to repair and patch

- Compact storage

- UV Stabilised hardwearing

- Supplied with copper anti-static wire for electrical continuity

- Available in different colours

Applications & Uses

- Refuelling truck, rail & ship

- Fuel Terminals & Depots

- Bulk Fuel Distribution

- Ship to Shore transfer

Specifications

| Colour | Green, Blue, Black |

| Working Temperature | -50C deg to 65C deg |

| Static Protection | Incorporates anti-static wire |

| Chemical Resistance | Resistant to hydrocarbons and most chemicals |

| Impact Damage | High abrasion resistance |

| Ozone Properties | UV stabilised |

| Handling | Easy to handle & roll |

| Properties | Lightweight, durable & maintenance free |

Comparable to Chemcoil 1200 of Angus

| NOMINAL | THICKNESS | WEIGHT | WORKING PRESSURE | |||

| inches | mm | inches | mm | lbs/ft | kg/m | psi/bar |

| 3″ | 76 | 0.18″ | 4.5 | 0.78 | 1.16 | 400psi/28bar |

| 4″ | 103 | 0.20″ | 5.2 | 1.29 | 1.93 | 400psi/28bar |

| 6″ | 154 | 0.23″ | 5.9 | 2.26 | 3.37 | 400psi/28bar |

| 8″ | 204 | 0.24″ | 6.2 | 3.50 | 5.21 | 400psi/28bar |

A Outside Polyurethane Cover

B Reinforcement Jacket

C Inside Polyurethane Tube

D Copper Wire